The Project: Air Quality Support Services – Stack Testing

📍Textile Plant, Schuylkill County, PA

The Challenge

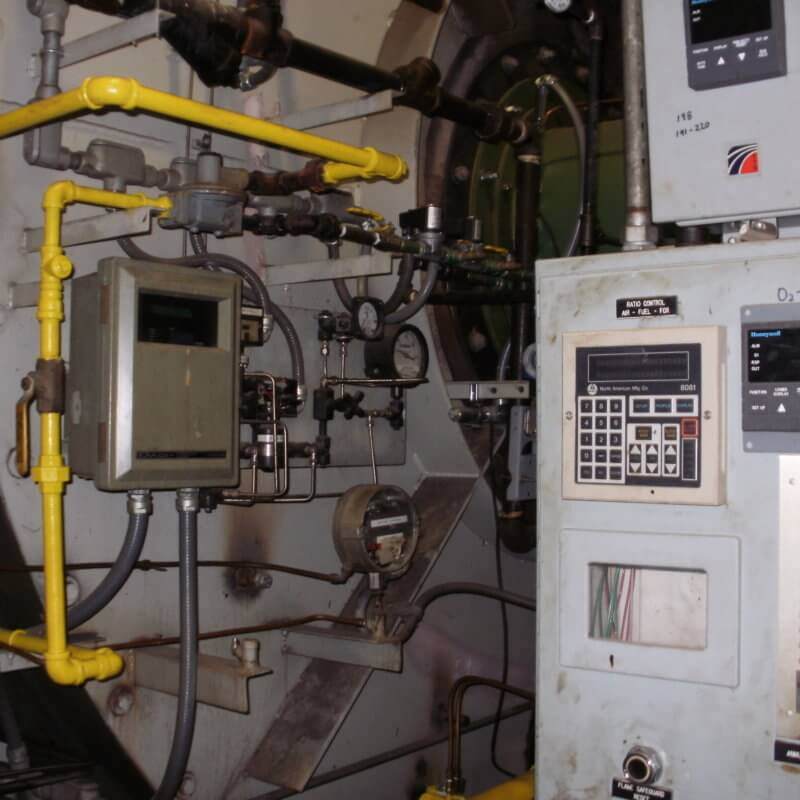

Enable the client to switch to complete or partial use of cost-effective renewable landfill gas in their plant. In order to do this, EARTHRES would have to prove that a new steam boiler operating on 100% landfill gas and hot oil heater, running on a combination of landfill gas and propane, are within permitted emission limits for NOx, CO, and NMOC’s.

Project challenges included onsite notification of the firing of landfill gas in conjunction with existing fuel types, maintenance of working relations between the PA DEP and the stack testing firm, and difficulty in maintaining boiler load and firing rate, which resulted in rescheduling the test for a weekend morning when plant production was at its highest demand for the week.

The Solution

EARTHRES provided air quality support services for stack emissions testing of a new steam boiler when firing 100% landfill gas at a textile plant located in Schuylkill County, Pennsylvania. Support services included solicitation of stack testing bids, selection of a stack testing firm, review and submittal of a pre-test protocol, and follow-up on protocol approval with the PA DEP, including response to comments and coordination of a teleconference among all involved parties.

Compliance of Boiler Operation on 100% Landfill Gas

EARTHRES coordinated testing with the site, stack testing firm, PA DEP Source Testing Group, and PA DEP Northeast Regional Office, and provided onsite stack testing oversight, including the recording of process data and gathering of landfill gas quality data from the facility’s landfill gas supplier. The unit was tested at a 30% firing rate firing 100% landfill gas. Test results showed that the boiler demonstrated compliance with its permitted emission limits for NOx, CO, and non-methane organic compounds (NMOCs). EARTHRES handled the final test report review and submittal, and response to PA DEP questions and comments on the final report.

Compliance of Heater Operating on Combined Landfill and Propane Gases

This stack testing process was repeated for the plant’s existing hot oil heater, whose burner was replaced to allow the unit to fire landfill gas in combination with propane in addition to No. 2 fuel oil as a backup fuel type. After the first attempt at testing could not be completed due to burner malfunctions, the unit was ultimately tested when firing an average of 90% landfill gas and 10% propane at a 30% firing rate. EARTHRES was instrumental in negotiating the allowable firing rate and confirming the proper calibration and fuel combinations of the burner. Stack testing was conducted on a Sunday morning when the plant’s tenter frames startup for the week’s production, in order to create the highest possible demand for heat and thus fire the heater at as high a firing rate as possible. The heater demonstrated compliance with its permitted NOx, CO, and NMOC emission limits.

The project also included the filing of an administrative amendment to incorporate plan approval terms and conditions into the plant’s state only operating permit following stack testing and general air quality compliance support.

The Results

The company is seeing operating cost savings with the switch to partial use of cost-effective landfill gas. This is due to proving compliance of the textile facility’s boiler and heater being within permitted emission limits for NOx, CO, and NMOCs when utilizing renewable landfill gas.

.png)