Project Background

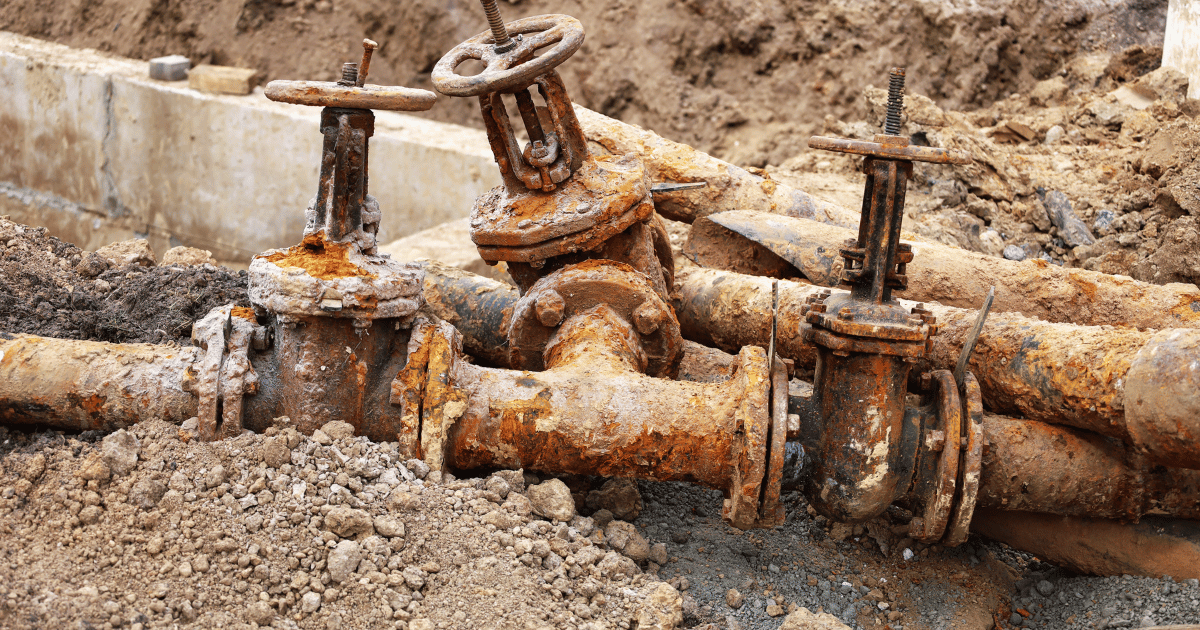

Maintaining the mechanical integrity of natural gas pipelines is critical for ensuring the safety, reliability, and efficiency of energy infrastructure. Corrosion poses a significant challenge to metal gathering and transmission lines, which often span hundreds or even thousands of miles, both above and below grade. Cathodic protection (CP) systems serve as an essential defense against this threat, diverting corrosion from the pipeline to a sacrificial anode. However, these systems require constant vigilance, including routine monitoring, inspections, and adjustments, to remain effective.

EARTHRES helped a client address significant issues within their CP system, ensuring optimal performance and mechanical integrity while reducing risks and costs associated with pipeline downtime and repairs.

The Challenge

Natural gas pipeline systems are highly susceptible to corrosion due to their extensive metal infrastructure exposed to varying environmental conditions. Effective corrosion control requires robust CP systems. However, these systems face complications such as interference from high-voltage overhead electrical lines, which can disrupt their performance.

During a routine preventative maintenance inspection of their CP system, the client discovered that key components were malfunctioning. To ensure their pipeline’s integrity and avoid potential damage from corrosion, the client engaged EARTHRES to diagnose the problem and implement a solution.

The Solution

EARTHRES CP-certified engineers provided a comprehensive suite of services to address the challenges with the client's cathodic protection system. The solution involved multiple phases, including diagnostics, repairs, and long-term planning.

Key actions taken included:

- Diagnostics and Field Analysis: EARTHRES performed an in-depth field analysis, including visual inspections, direct current (DC) structure-to-soil potential measurements, and evaluations of existing rectifiers' DC outputs. The team also repaired long-term test stations and identified short-circuiting issues within the system.

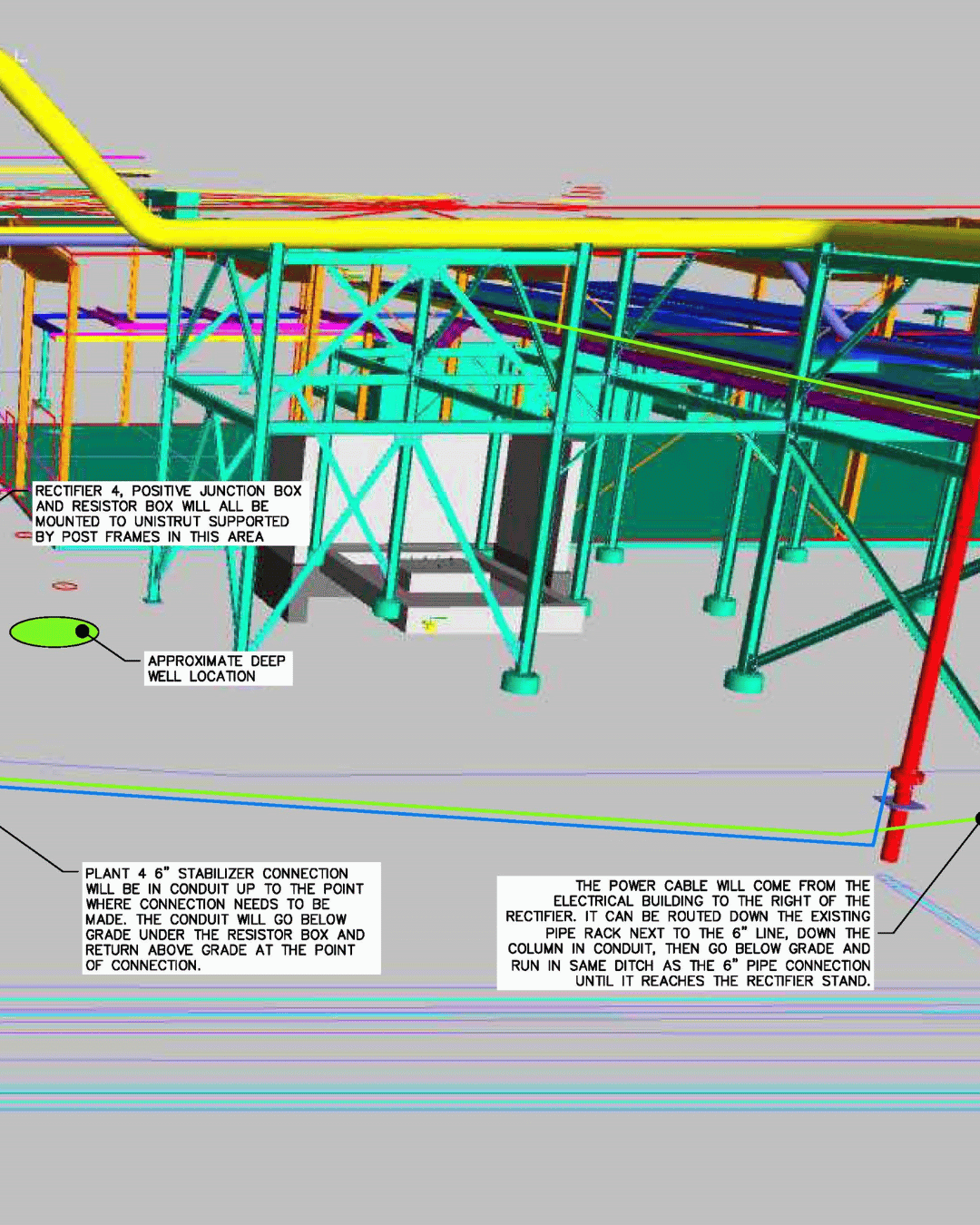

- CP System Design and Installation: EARTHRES designed a new impressed current rectifier system tailored to optimize the client's CP performance. This included field repairs of anodes, adjustments to the rectifier’s current output to counteract AC interference, and replacement of failed insulated flanges.

- System Optimization and Training: EARTHRES fine-tuned the CP system through rectifier tuning and continued monitoring. Additionally, the team compiled compliance documentation, developed an ongoing maintenance schedule, and provided training to the client’s staff on CP system management.

These efforts ensured the CP system’s immediate functionality while laying the groundwork for continued performance optimization.

.png?width=1080&height=1350&name=CP3_Compressed_Compressed%20(2).png)

The Results

By partnering with EARTHRES, the client achieved several impactful outcomes that enhanced the safety, reliability, and cost-effectiveness of their operations.

Key Benefits:

- Ensured Corrosion Protection: The newly designed and optimized CP system safeguarded the pipeline from corrosion, eliminating the immediate risks of mechanical failure and pipeline downtime.

- Reduced Maintenance Burden: The client could now focus on routine operations without dedicating non-CP-certified staff to system management. EARTHRES’ expertise ensures that the CP system continues to function effectively under their oversight.

- Cost Savings: By preventing potential corrosion issues, the client avoided substantial repair costs and minimized the risk of unplanned downtime, resulting in long-term cost savings.

- Enhanced Knowledge Transfer: Through EARTHRES’ staff training, the client gained a better understanding of CP system operation, enabling more informed decision-making.

Routine monitoring and precise field interventions are critical to preventing small issues from escalating into major problems.

Click the link to learn more about our Cathodic Protection Services.

Are you facing similar challenges with your pipeline infrastructure ?

Let us help you! Get in touch with our experts and learn how we can help you ensure safety and stability at your facility.